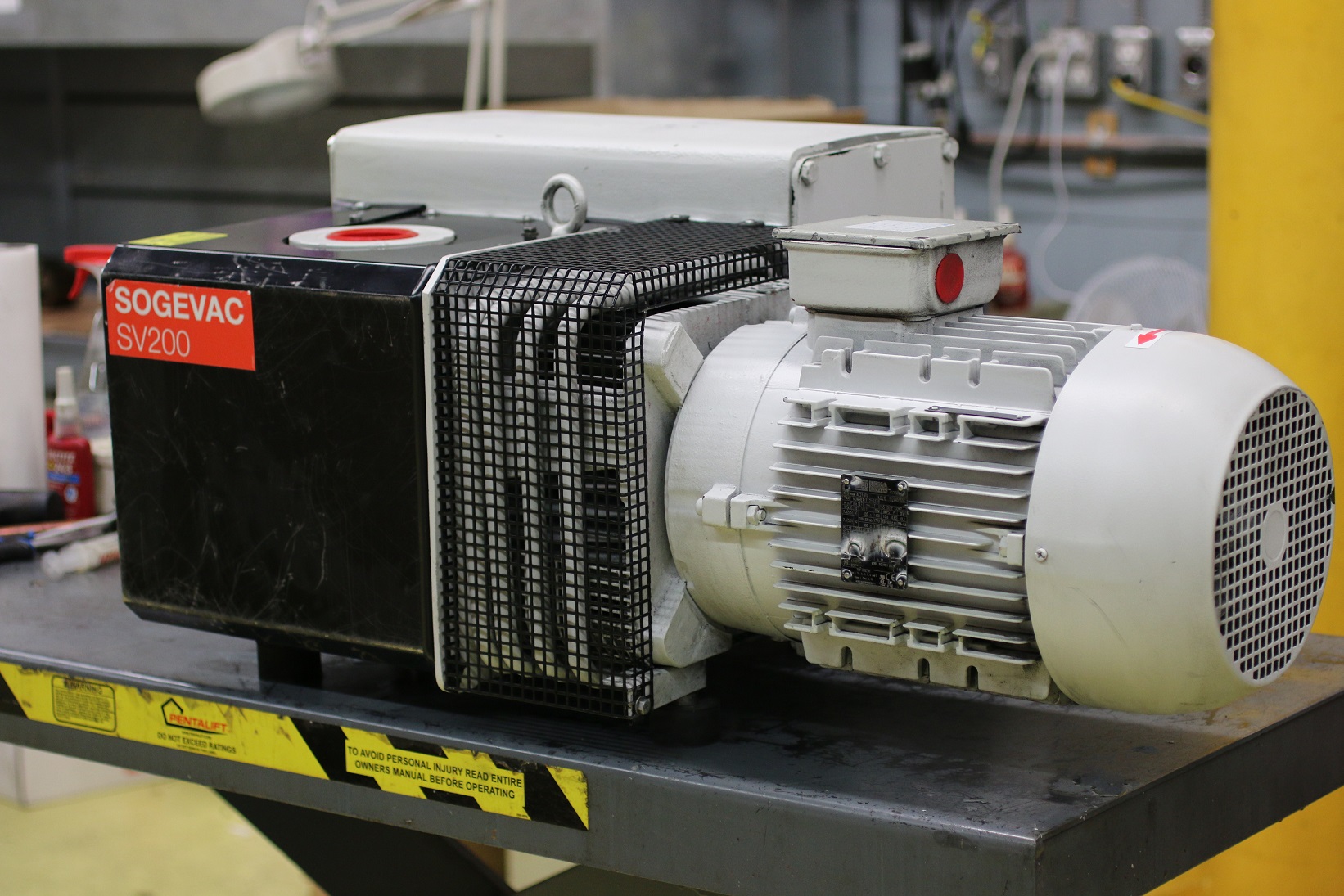

The Intlvac Vacuum Pump Repair Process

Your vacuum pump isn’t working. Or maybe it’s making a strange noise that you haven’t heard before. Perhaps the pump is functioning below the standard you are used to. Any one of these reasons might prompt you to call Intlvac to get your vacuum pump serviced.

Your vacuum pump isn’t working. Or maybe it’s making a strange noise that you haven’t heard before. Perhaps the pump is functioning below the standard you are used to. Any one of these reasons might prompt you to call Intlvac to get your vacuum pump serviced.

Chances are that there's plenty of life left in your pump and Intlvac will help you maximize its value and extend its life. Here’s a step-by-step process for how we handle a standard pump repair:

- First, we do a complete tear-down of your pump, removing all toxic materials and safely disposing of them according to applicable safety regulations.

- We then conduct a full vacuum pump evaluation.

- Intlvac sales staff prepare a service quotation based on the pump evaluation.

Next comes a complete part degreasing in our chemical industrial parts washer ensuring that all working surfaces are clean and free of debris.

Next comes a complete part degreasing in our chemical industrial parts washer ensuring that all working surfaces are clean and free of debris.- Consumable parts such as o-rings, gaskets, shaft seals and bearings are replaced.

- Depending on the condition of each component, Intlvac may replace wearing parts such as rotor, stator, end-plates, centre plates, housing, motor, sight glasses, exhaust valves, gas ballast assemblies, dirt traps, pistons, cams, slide valves, gears etc.

- If further assessment reveals the need for additional parts where further costs may apply, the customer will be contacted for approval prior to replacing those parts.

- Once all approvals are received, the pump is rebuilt to factory specifications using manufacturer original parts wherever possible.

- Our trained service professionals check pump operation and complete a full assessment report. 24 Hour testing is conducted to ensure optimal operation.

Upon meeting Intlvac’s quality standards, the pump is re-labeled and prepared for return to the customer.

Upon meeting Intlvac’s quality standards, the pump is re-labeled and prepared for return to the customer.- A complete one-year warranty against parts and labour defects is provided (Subject to warranty evaluation.)

If you would like to send your pump in for repair evaluation, please complete our Service Request Form found on any of our Service repair pages. We will contact you within 24 hours or as soon as possible to discuss next steps.

Related

The history of Leybold spans a period of over 165 years. Innovative vacuum technology was continuall...

Read More >

From time to time Intlvac would like to offer our customers opportunities to learn about vacuum pump...

Read More >

Freeze drying, also known as lyophilization, is a crucial process in various industries, including p...

Read More >

How involved is vacuum in the drying process for cannabis? Take a look at this blog post from Leybol...

Read More >

An oil-free screw is a type of vacuum pump that uses a pair of intermeshing screws, or rotors, to co...

Read More >

Intlvac Delivers High Vacuum Systems for Physical Vapor Deposition and Ion Beam Milling and has beco...

Read More >